Industry 4.0

Dyna IDCS

DYNA-IDCS : Intelligent Distributed Control Training System

- Intelligent Industrial controller mounted on ESD protective

Workbench - On-board 24V 6A Power-Supply

- I/O Signals brought out on breakout panels for interfacing

- PLC Programming IEC-61131-3 standards with KW-Multiprog

- Provision for Industry standard DIN-rail mounted units

- Examples for PLC Programming & LabVIEW based Experiments

Included. - Ergonomic Design with Ease of Interfacing

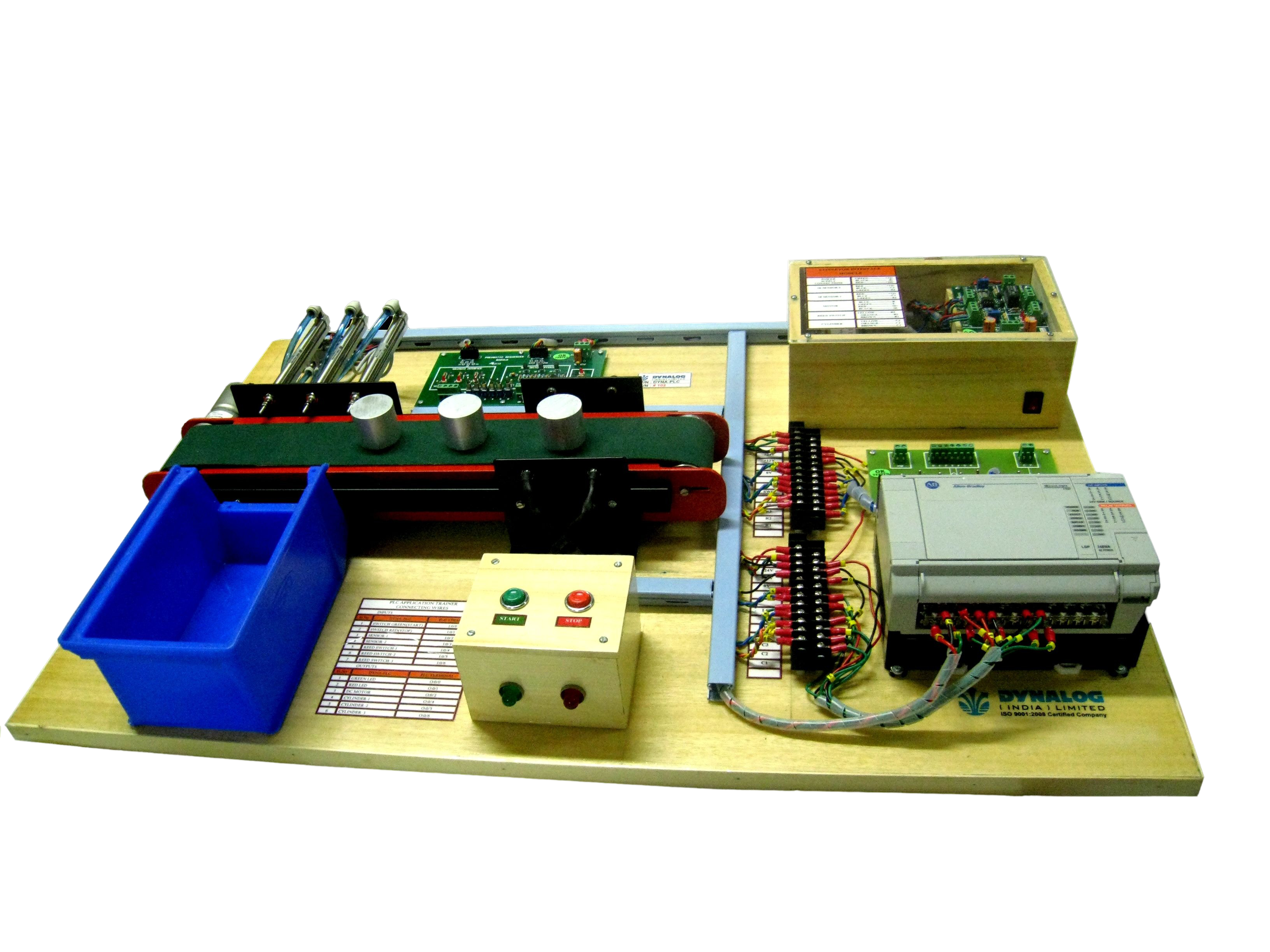

Dyna PLC

DYNA-PLC : Programmable Logic Controller

- DYNA-PLC Applications trainer with Conveyor belt having forward & reverse directions.

- Three Pneumatically Controlled Pistons, for pushing parts off the conveyor.

- Two sets of infra-red Parts sensors.

- Set of Cylindrical Parts along with Parts bin for sorting parts into different categories.

- Run / Stop switches with Indicator lamps.

- Seven SPDT Switches which can be used to manually control the inputs of the PLC, in order to

simulate a various Input Conditions. - On board Sensors indication LEDs

- On Board 10K Knob Potentiometer A(0-10V)

AIR CONDITIONING TRAINER

Distributed Control Training Systems - The SIMATIC S7-1200, CPU 1214C, COMPACT CPU, DC/DC/DC controller,

- ONBOARD I/O: 14 DI 24V DC; 10 DO 24 V DC; 2 AI 0 - 10V DC, Timers, and Counters &

Sequencer Functions.

- The controller is supplied with Programming Software, which is used to Program, Monitor, Edit &

Troubleshoot Sequences for practical exercises. - An Interface RJ45 cable that connects the controller to the computer is included.

- Electrically Operated compressed air pump provides a safe source of compressed air.

- The PLC application trainer enables students to create Sequences which simulate the operation of a modern Industrial Production line

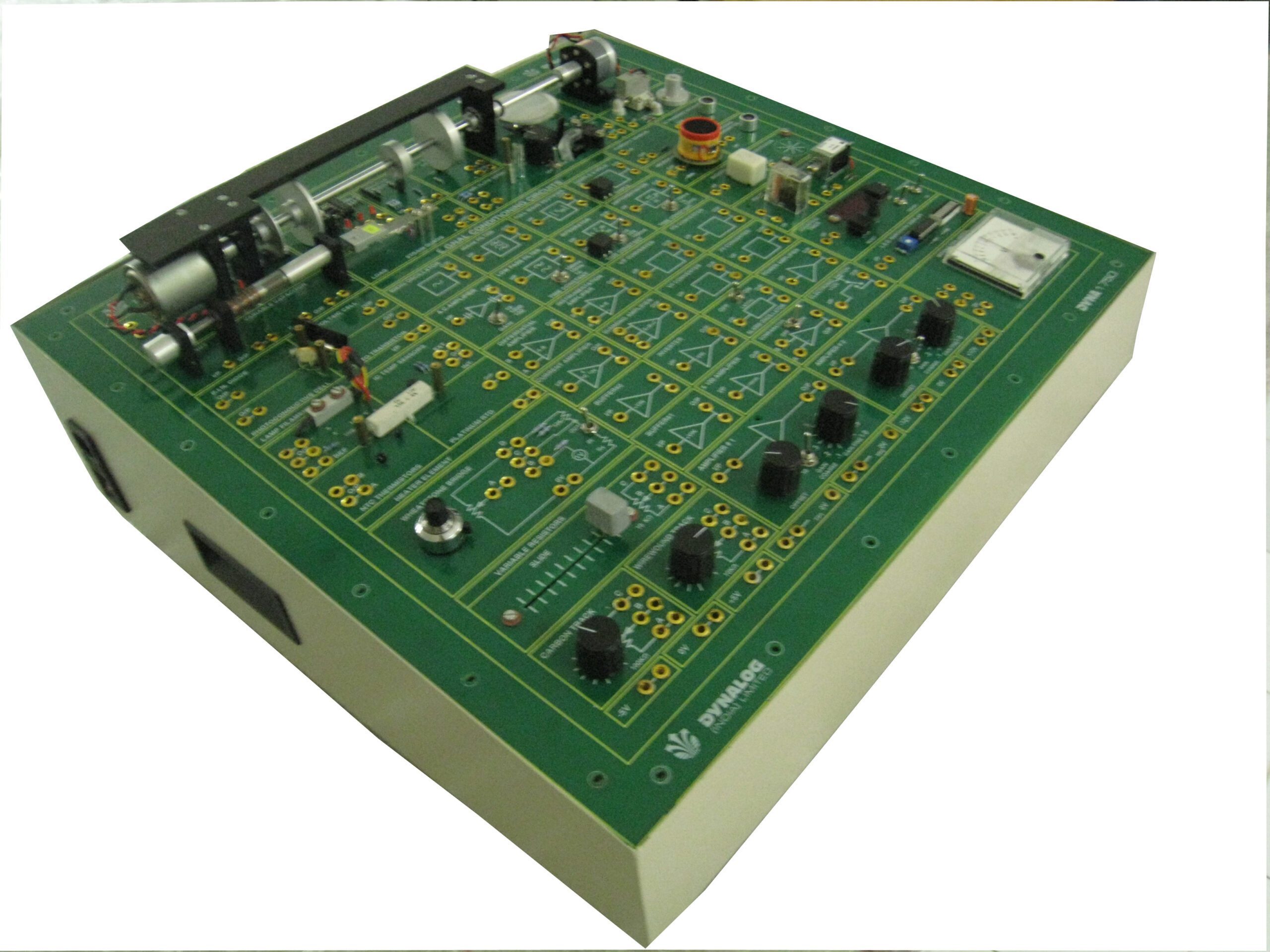

Dyna TnIT

DYNA-TnIT : Transducer & Instrumentation Trainer.

- The bench-mounted trainer features the following Input devices and circuits ;

- Carbon Track, Wire Wound, Precision Rotary & Slide potentiometers.

- RTD resistance transducer, NTC Thermistors, 'K' Thermocouples, I.C. Temperature Sensor,

- PIN diode, Photoconductive cell, Photovoltaic cell, Phototransistor.

- Linear Variable Differential Transformer & Linear Variable Capacitor

- Strain Gauge, Air-Flow Sensor, Air pressure sensor

- Slotted Opto-Sensor, Reflective Opto-Sensor

- Inductive Proximity Sensor, Hall Effect sensor

- Precision Servo-Potentiometer Techo Generator

- Humidity sensor

• Dynamic microphone

• Ultrasonic receiver

The Trainer features following Output devices ;

• Heater,

• Filament Lamp

• DC Motor

• Solenoid Air Valve,

• Relay,

• Solenoid

• Ultrasonic transmitter

• Buzzer

• Loudspeaker

• Counter/timer unit with LED display

• Bar Graph voltage indicator

• Analog 10V center-zero meter

The Signal Conditioning Circuit section consists of ;

• Buffers, Inverters,

• Comparator with Switchable Hysteresis

• Amplifiers With Gain & Offset Control

• Current, Summing, Differential, Power, AC and Instrumentation Amplifiers

• Oscillator 40 kHz, Filter 40 kHz, Low-Pass Filter with Switchable Time Constant.

• Precision Full-Wave Rectifier,

• Sample & Hold Circuit

• Electronic switch

• Integrator with Switchable Time Constant

• Differentiator with Switchable Time Constant

• V/F & F/V converters, V/I & I/V converters

• Alarm oscillator with switch able latching

AIR CONDITIONING TRAINER

Distributed Control Training Systems

Internal Power supply of Trainer provides +/-5V, 1A precision supply and +/-12V, 1A regulated supply. Pneumatic

Pump also included.

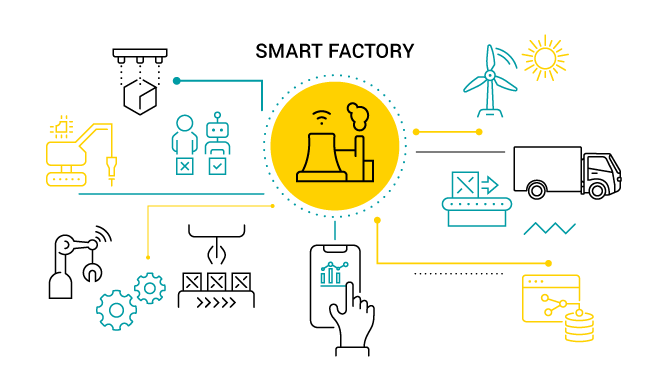

Dyna-Smart Factory

Embedded sensors on machines and throughout the production line to capture data on parameters like temperature, pressure, vibration, and product quality in real-time, with actuators responding to data inputs to adjust processes accordingly.

Industrial IoT (IIoT) Network:

A robust network infrastructure to connect all sensors, machines, and devices, enabling seamless data transmission and communication across the factory floor.

Edge Computing:

Data processing capabilities at the edge of the network, allowing for faster decision-making and immediate response to production fluctuations.

Utilizing algorithms to analyze large volumes of real-time data, identifying patterns, predicting potential issues, and optimizing production parameters.

Ready to find out more?

Drop us a line today for a free quote!